Unsound concrete can be identified through various signs such as visible cracks, micro-cracks, spalling, scaling, blisters, and delamination. Multiple factors lead to different types of damages, and as a result, a specific repair strategy may be required for each type of concrete damage.

Major Signs of Unsound Concrete

1. Visible CracksVisible cracks are the most apparent symptoms of unsound concrete and have several causes. For instance, impact or heavy loads can initiate visible cracks immediately or cause micro-cracks that develop into visible cracks.

In addition, surface cracks are caused by the quick loss of water from the concrete surface during the curing process. Moreover, subgrade settlement leads to crack development in concrete slabs. Finally, restraint to a contraction in concrete elements is another factor that exacerbates crack propagation.

Figure-1: Visible Cracks on Concrete Surface

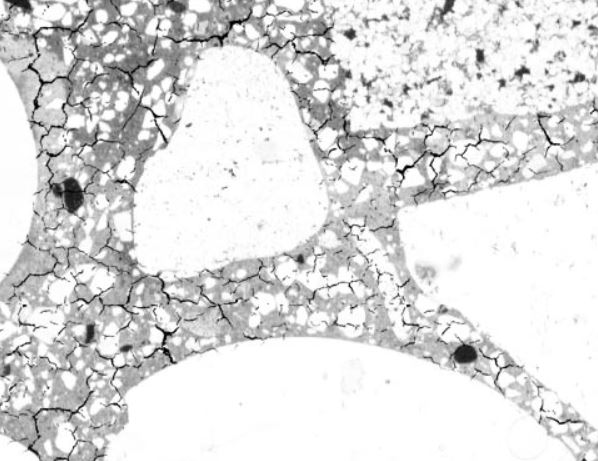

2. Micro-cracksMicro-cracks are invisible to the naked eye and are measured on the scale of microns. Possible causes of micro-cracks in concrete structures are overloading, freezing, and thawing, temperature differentials during cement hydration, and impacts from dropped loads and impact tools like scrabblers.

Concrete bruising occurs when micro-cracks create a network near the surface. After that, the concrete may crumble away, subsequently, exposing the aggregates.

Figure-2: Microcracks on Concrete Surface

3. Blisters Blisters appear when bubbles of entrapped air or water rising through the plastic concrete get trapped under an already sealed, airtight surface.

Factors contributing to the formation of blisters are an overly sticky concrete mixture that seals the surface quickly, carrying out finishing works when the concrete is still spongy, and insufficient vibration during compaction that fails to release entrapped air.

Figure-3: Blisters on Concrete Surface

4. Delamination

Delamination is a hollow, horizontal plane underneath the concrete surface. It is formed when the finishing begins before water and air escapes from the concrete.

Other causes of delamination are cold substrate which extends the concrete bleeding time, and high ambient temperature that accelerates the concrete setting.

Due to heavy loads, delaminated concrete may be detached from the concrete slab, and as a result, the aggregates are exposed.

Figure-4: Delamination of Concrete Surface

5. Scaling Scaling is the loss of near-surface concrete due to its exposure to freezing and thawing. As the water in concrete pores freezes and hydraulic pressure of expanding ice surpasses the concrete tensile strength, scales of mortar break away from the surface and expose the aggregate.

The causes of scaling are exposure of concrete to repeated cycles of freezing and thawing, the use of deicers, and a high water-cement ratio.

Figure-5: Scaling of Concrete

6. Spalling Spalling is similar to scaling, but the depth of concrete detaches from the concrete surface is greater. Causes of spalling are reinforcement corrosion, violent moisture evaporation in concrete due to intense heat, improperly constructed joints, and crack deterioration.

Figure-6: Concrete Spalling

How to Determine the Extent of Unsound Concrete?The above signs may indicate concrete damage, but the full extent of the damage is not always clear. That is why specific simple testing techniques may be needed.

1. Tap the surrounding of a visibly weak concrete area with a hammer. If the hammerhead bounces, the concrete compressive strength is good. However, if the hammer’s head pulverizes the concrete surface, the concrete is unsound and weak.

2. Listening to the sound generated by the hammer can reveal areas of different densities. This technique can be beneficial to specify pockets of air, water, or unwetted material that is formed under the concrete surface.

3. Apply or drag a screwdriver across the concrete surface. If it scratches off the power, the concrete is unsound. However, if it creates a shiny white streak, the concrete is sound.

FAQs

What are the major signs of unsound concrete?The common and major signs of unsound concrete are visible cracks, micro-cracks, spalling, scaling, blisters, and delamination.

What are the causes of micro-cracks?

Possible causes of micro-cracks in concrete structures are overloading, freezing, and thawing, temperature differentials during cement hydration, and impacts from dropped loads and impact tools like scrabblers

How can you tell if the concrete is spalling?Inspectors can see chipping, flaking, and large chunks of concrete missing from the concrete surface, resulting in exposure of coarse aggregate.